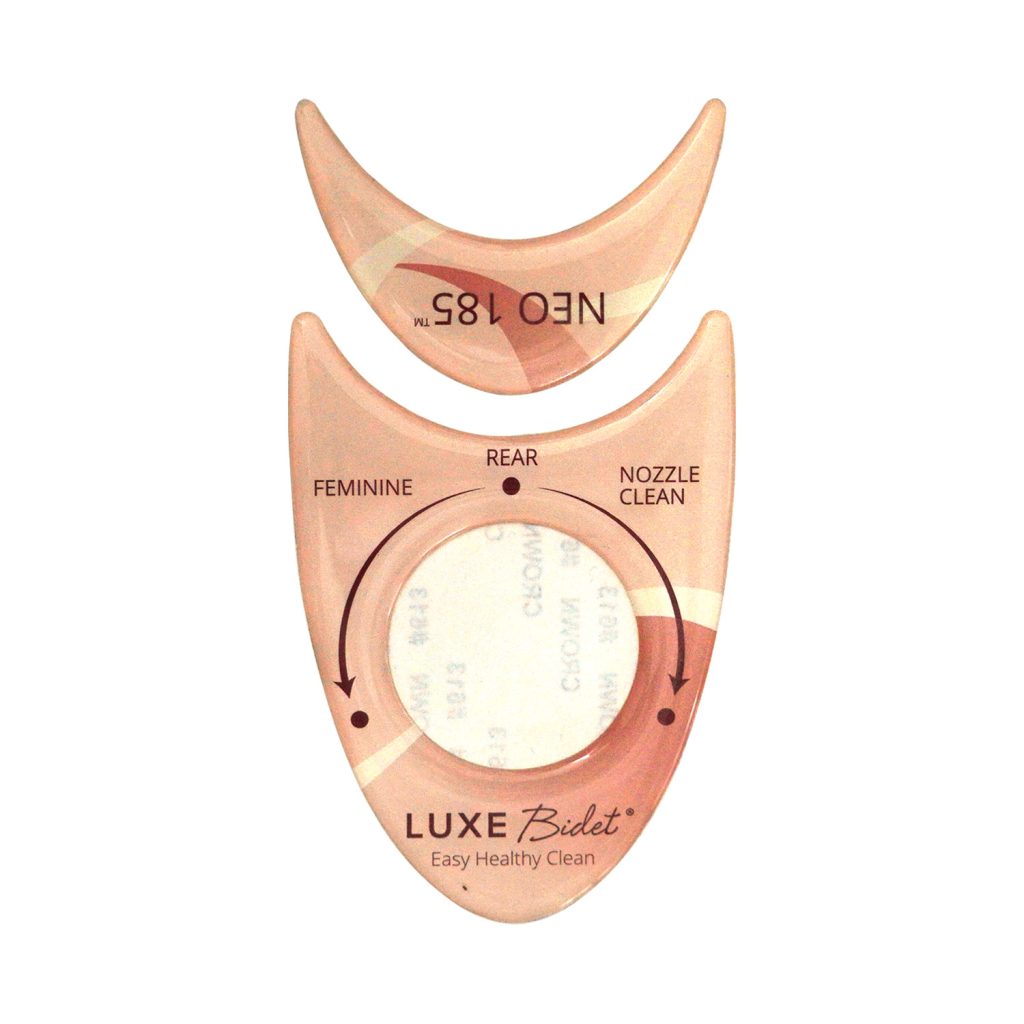

The product introduced today is a crystal dome label product designed in cooperation with the LUXE bathroom brand for smart toilets. The function of this resin dome label is to be installed at the smart control on the side of the toilet to help customers use smart toilet products more easily and conveniently.

In today’s pursuit of high-quality life, every detail is particularly important, especially the bathroom facilities that are closely related to our daily health. As a bathroom product that combines modern technology and design aesthetics, the smart control design of LUXE’s smart toilet is also very practical and advanced. From the appearance of the crystal resin label, it can be seen that the blue tone is matched with the functional design of different texts, and “REAR NOZZLE FEMININE CLEAN” clearly points out the function and use of the product. Among them, “REAR” refers to the rear, “NOZZLE” refers to the nozzle, “FEMININE” refers to women-only, and “CLEAN” emphasizes the cleaning function. With its unique self-cleaning function, dual nozzle design, non-electric toilet connection compatibility, adjustable water pressure, and washing mode designed specifically for the rear and women, it redefines the convenience and hygiene standards of home bathrooms.

In terms of the production of epoxy label, Bx also gained more new insights:

- Design and planning Determine the design: First, design the appearance and pattern of the adhesive dome label according to the characteristics of the product and the brand requirements. This includes elements such as colors, shapes, text, and patterns. Material selection: Select the right material, such as transparent or translucent plastic film, PET material or other material suitable for crystal effect. At the same time, it is also necessary to consider the material’s weather resistance, corrosion resistance and whether it is compatible with the product surface.

2. Prepare Preparation for printing: The designed clear resin label pattern is processed through professional software to prepare the file for printing. This may include adjusting colors, resolutions, and file formats. Mold making (if applicable) : For dome label sticker that require a particular shape, molds may need to be made. The production of molds usually relies on precision machining or 3D printing technology.

3. Printing and production Printing: Use professional printing equipment to print epoxy label sticker design patterns onto selected materials. This may include a variety of methods such as lithography, intaglio printing, screen printing or digital printing. Molding: If the 3D dome label needs to have a specific three-dimensional shape (such as a dome shape), it needs to be molded. This is usually achieved through processes such as thermoforming or vacuum forming, where the material forms the desired shape after being softened by heat in a mold.

4.Back adhesive according to the use of the product environment and requirements, choose the appropriate type of back adhesive, such as waterproof, temperature resistance, super bonding, etc. We offer 3M, Crown, Soken, Nitto, Sony, Luxking and other adhesive brands.