In the fast-paced modern life, cooking has become a luxury. However, Haier dishwasher, with its unique design and powerful functions, has brought us unprecedented convenience and delicious experience.

Today, let’s take a deeper look at this exciting dishwasher. The functions of Haier dishwasher are not limited to simple washing. It also has an intelligent control system that can automatically adjust the washing intensity and water consumption according to the time and mode set by the user to achieve the best cleaning effect. In addition, the dishwasher is also equipped with an efficient drainage system to ensure that the sewage in the washing process can be quickly discharged to keep the interior of the dishwasher clean and hygienic.

As an old-fashioned enterprise, Haier also has close cooperation with XINBIXI. This dishwasher graphic overlay panel is completed by Haier and XINBIXI.

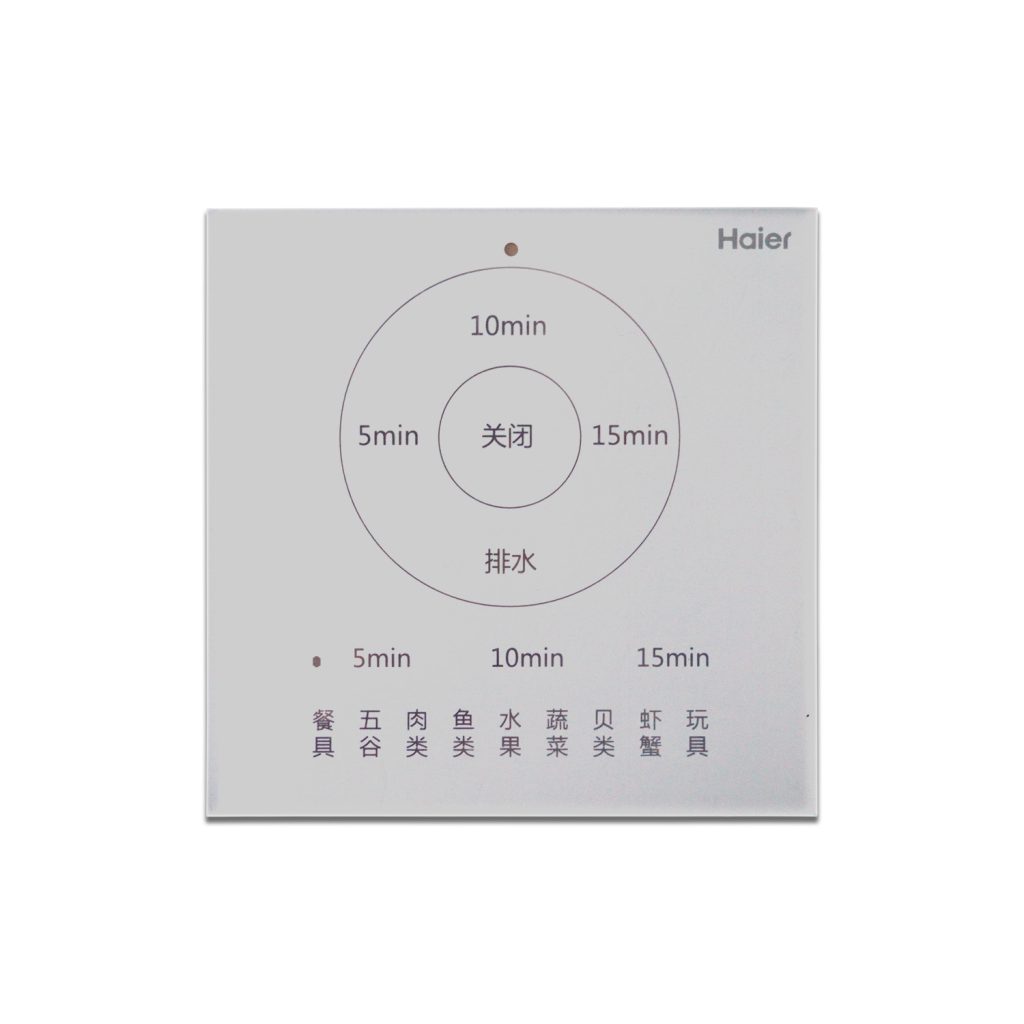

First of all, from the appearance, the graphic overlay panel adopts a simple and clear design style. On the white square panel, the black text and numbers are clearly visible, making the operation process clear at a glance. The large circle in the center of the panel is marked with different time marks, indicating that the dishwasher has a timing function, which can accurately control the washing time and ensure the cleanliness of the tableware. At the bottom of the graphic overlay panel, it is marked that in addition to tableware, the dishwasher can also wash a variety of different vegetables, fruits, seafood, and even toys. Powerful functional design makes this product more perfect.

The materials used for this Haier dishwasher graphic overlay panel are as eye-catching as its design. In order to match the material of the dishwasher, we used acrylic as the base material of the graphic overlay panel. Acrylic, known as plexiglass, has a function close to glass but is safer and more durable.

The font on the surface of the graphic overlay panel is gray, the surface is clear and free of impurities, and the font partition design is also very clear at a glance.

This Haier dishwasher graphic overlay panel is also very sophisticated in production:

Start Material:

Use a cutting machine or laser cutter for precise cutting of Acrylic&PMMA sheets to ensure accurate dimensions and reduce material waste. Laser cutting machines are often used because of their high accuracy and low material loss.After cutting, remove the protective paper on the surface of the plate and prepare for subsequent processing.

Engraving/Cutting:

According to the design pattern or graphics, the Acrylic&PMMA sheet is initially carved or cut using a laser engraving machine or a mechanical cutting machine. Pay attention to control the temperature and ventilation of the engraving machine to prevent the board from burning.

Trimming:

The edge of the carved or cut sheet is often rough, and it is necessary to use a trimming machine to trim the edge to ensure smooth edges and avoid scratching hands.

Polish:

After trimming, the sheet is polished to eliminate the roughness of the surface and improve the gloss.Polishing methods include grinding wheel polishing, cloth wheel polishing and fire polishing, etc. The specific selection needs to be determined according to product requirements.

Screen printing:

If you need to print patterns, text or LOGO on Acrylic&PMMA products, you can use screen printing technology. Screen printing is divided into monochrome, multi-color (such as four-color CNYK) and thermal transfer and other ways, can be selected according to specific needs.

Cleaning:

Clean the powder, debris and other impurities generated during processing to ensure that the surface of acrylic&PMMA lense products is clean.

Packaging:

The finished product is packaged to protect it from damage during transportation and storage.

Special surface treatment technology

The acrylic&PMMA panels with different functions need some necessary surface treatments such as spraying, electroplating, laser engraving and surface texture treatment. These treatments can improve the durability and user experience of the graphics overlay.

Back adhesive:

According to the use of the product environment and requirements, choose the appropriate type of back adhesive, such as waterproof, temperature resistance, super bonding, etc. We offer 3M, Crown, Soken, Nitto, Sony, Luxking and other adhesive brands.