Metal nameplates are nameplate products made of materials such as copper, iron, aluminum, zinc alloy, titanium, nickel and stainless steel. Metal nameplates play an important role in people’s daily lives with their wide range of applications and unique characteristics. With the continuous advancement of science and technology and the continuous innovation of technology, the production and application of metal nameplates will become more diversified and personalized.

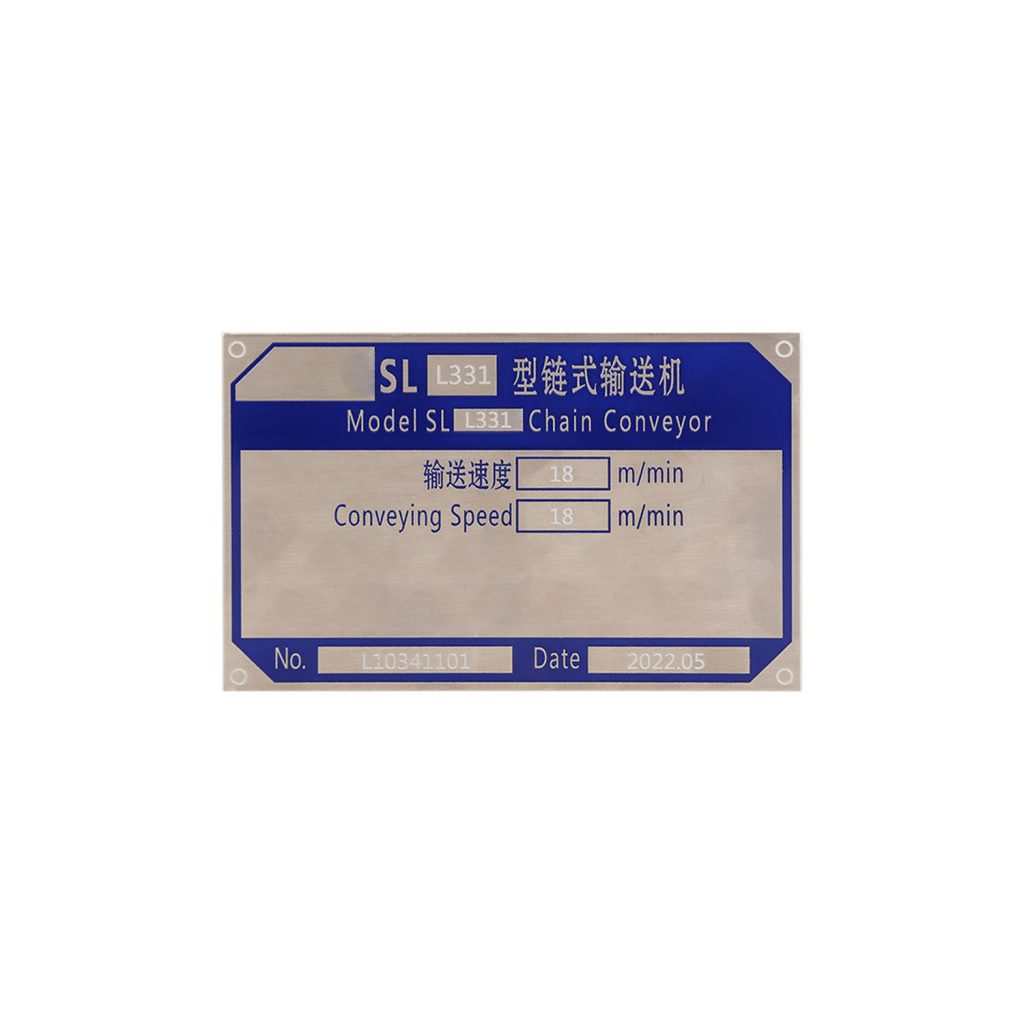

Today I will introduce you to a metal nameplate used in large machinery.

Metal nameplates on mechanical equipment play a vital role. They not only provide key information, but also enhance the overall quality of the equipment. There are more important roles and characteristics:

I. Function

1. Provide identification and information:

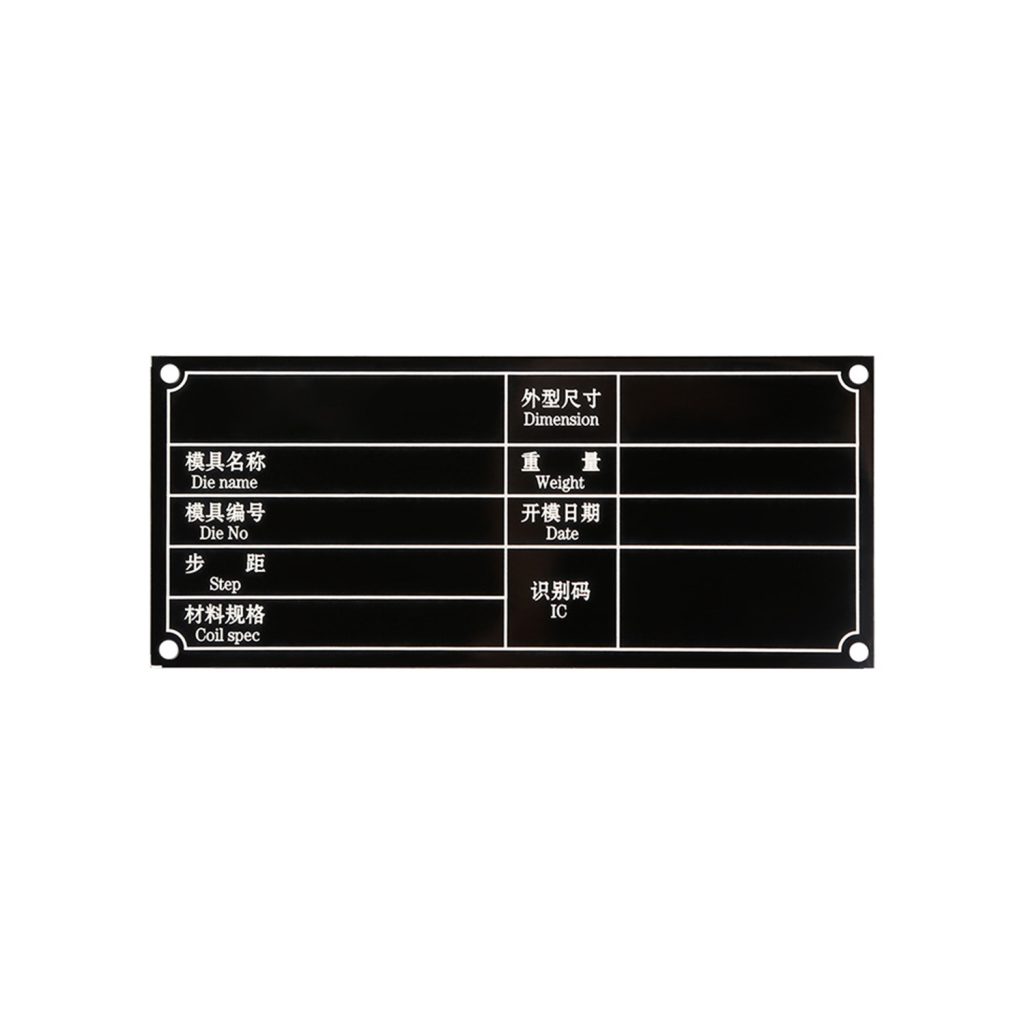

The mechanical metal nameplate records the basic information of the machine, such as the name, model, serial number and specifications. The nameplate identification can effectively prevent the misoperation of mechanical equipment during use.

The nameplate also lists the personnel information of dealers, parts personnel and service technicians in the maintenance center, as well as manufacturing information such as production date and safety warnings, which facilitates the maintenance and maintenance of mechanical equipment.

2. Enhance the sense of quality and aesthetics:

During the production process, metal nameplates, as a decorative element, can add a high-quality appearance to mechanical equipment, making the mechanical equipment look more commercial and high-end.

3. Comply with regulatory requirements:

In some countries and regions, mechanical equipment must have metal nameplates. Since metal nameplates can provide important information identification and safety warnings for mechanical equipment, they also have important value at the legal level.

Features

4. High strength:

nameplates made of some metals such as stainless steel have strong rigidity and can withstand large external forces, which are suitable for mechanical equipment that may be subjected to external forces. At the same time, stainless steel nameplates have a high melting point and can adapt to the high temperature environment that may be generated by mechanical equipment during operation.

5. Metallic luster:

Metal nameplates have a unique metallic luster, which looks full of craftsmanship and can enhance the overall aesthetics of mechanical equipment.

6. Diverse materials:

Mechanical metal nameplates are generally made of copper, stainless steel, aluminum, zinc alloy, etc., all of which have good corrosion resistance and durability.

7. Advanced processing technology:

The processing technologies of metal nameplates include laser engraving, chemical etching, CNC stamping and 3D printing, which can produce fine and durable nameplates.

Metal nameplates on mechanical equipment play an important role in providing key information, enhancing quality and aesthetics, and complying with regulatory requirements. At the same time, they also have the characteristics of high strength, metallic luster, diverse materials and advanced processing technology, which make metal nameplates an indispensable part of mechanical equipment.