In industrial production and mechanical equipment operation, safety is always the first priority. In order to ensure the safety of operators and the normal operation of equipment, the setting of emergency stop buttons is crucial. The accompanying labels are the key to remind operators to use emergency stop buttons correctly and in a timely manner. Next, let’s discuss the production and application of emergency stop button labels.

1. Production of emergency stop button labels

1. Material selection: Emergency stop button labels should be made of durable and non-fading materials, such as polyester film or synthetic paper. These materials not only have good waterproof and oil-proof properties, but also maintain the clarity of the labels in harsh industrial environments.

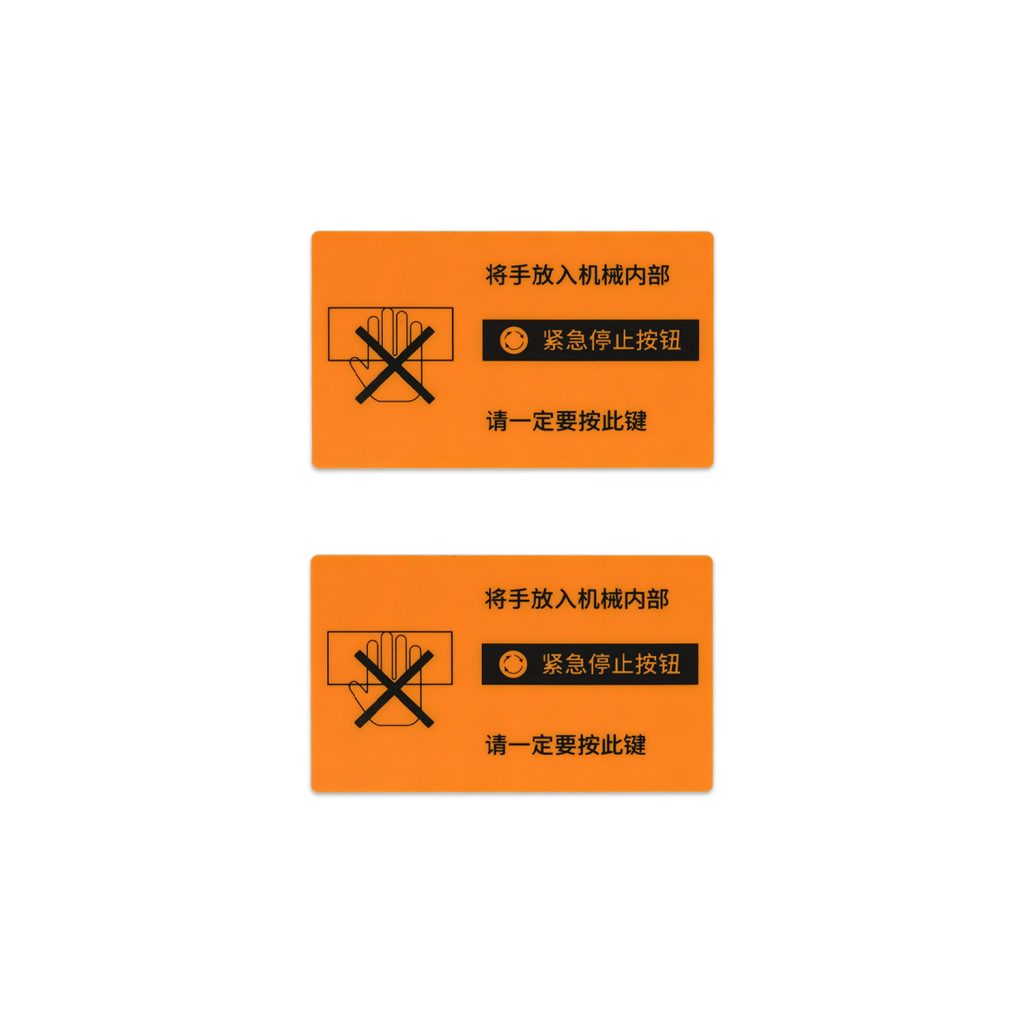

2. Color and font: The background color of the label is usually eye-catching orange or red to attract the attention of the operator. The font should be large, bold black font to ensure that it can be clearly seen from a distance. At the same time, the label should also contain necessary warning patterns, such as “no touch” gestures, to enhance the warning effect.

3. Content design: The content of the emergency stop button label should be concise and clear, directly pointing out the function and operation method of the button. For example, words such as “Please be sure to press this button” and “Emergency stop button” are supplemented with brief instructions or warning patterns. In this case, the label in the picture also mentions the specific scenario of “Put your hand inside the machine”, which further clarifies the conditions for the use of the emergency stop button.

4. Size and shape: The size of the label should be determined according to the actual size and position of the emergency stop button to ensure that the label can fit tightly on the button without affecting the normal operation of the operator. In terms of shape, regular shapes such as square or round are usually used to facilitate standardized production and installation.

2. Application of emergency stop button labels

1. Installation location: The emergency stop button label should be installed in a conspicuous position of the button to ensure that the operator can see it at a glance. At the same time, the label should be kept at a certain distance from the button to avoid being blocked or accidentally touched during operation.

2. Usage scenario: Emergency stop button labels are usually used on mechanical equipment with potential dangers, such as stamping machines, injection molding machines, cutting machines, etc. Setting emergency stop buttons and labels on these equipment can quickly cut off the power supply or stop the equipment in an emergency, thereby protecting the safety of the operator.

3. Training and publicity: Before the equipment is installed and used, operators should be given relevant safety training and publicity to let them know the function and use of the emergency stop button. At the same time, the safety awareness and operating skills of operators can be improved by posting safety posters and playing safety videos.

4. Regular inspection and maintenance: In order to ensure the effectiveness of emergency stop buttons and labels, regular inspections and maintenance should be carried out. The inspection content includes whether the button functions normally and whether the label is clear and intact. Once abnormalities or damage are found, they should be repaired or replaced in time.

In summary, the production and application of emergency stop button labels are of great significance to ensure the safety of industrial production and mechanical equipment operation. Through reasonable design, installation and maintenance, we can further improve the safety awareness of operators and reduce the occurrence of safety accidents.